Expertise and industrial capabilities

6,000 m² of production workshops in France

With industrial machinery made up of 60 looms, 30 printing machines and 25 making and cutting machines, we produce in France over 70 million metres of printed ribbons and over 100 million woven labels and accessories.

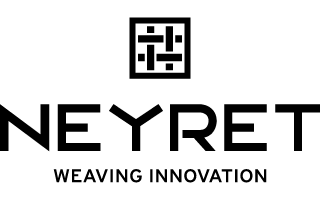

Cutting edge expertise: Jacquard weaving

NEYRET is steeped in weaving expertise which takes on several forms: wide Jacquard weaving for ultra-productive, very big industrial runs, the needle loom for special finishes and traditional shuttle weaving for silk in particular.

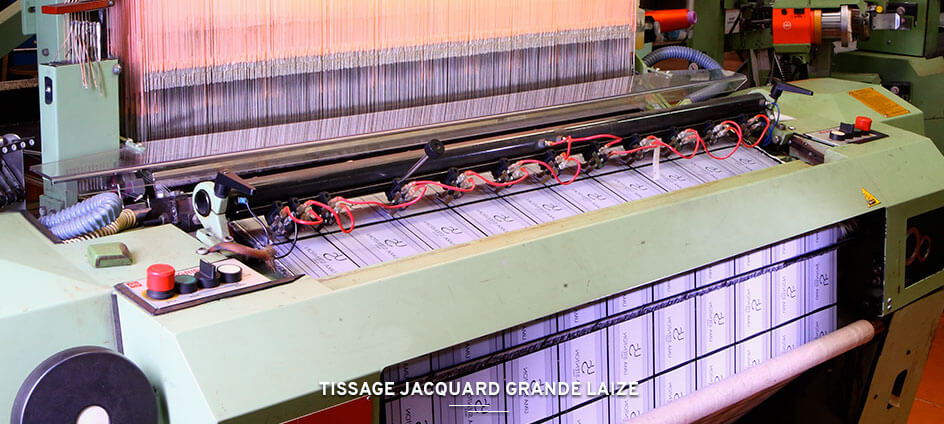

Narrow textile printing

We master all the printing techniques on ultra-productive industrial machinery designed and fine tuned by our in-house technical teams (silk screen, flexo, thermal transfer, digital printing, hot stamping, etc.). We have developed and patented the majority of our machines sometimes using advanced technologies to boost our industrial production capabilities with impressive product quality.

Plain weaving

We also have a workshop dedicated to plain weaving and fully master all the yarn preparation stages in our warping workshop.

Manual precision assembly

Our history vouches for our genuine expertise in the assembly of textile pieces. We are well used to sewing, tying, bonding, glueing… and assemble our ribbons to accessories, metal parts, cords and elastic bands. Currently fitted out with very high capacity assembly platforms, we can handle big volume projects with flexibility.

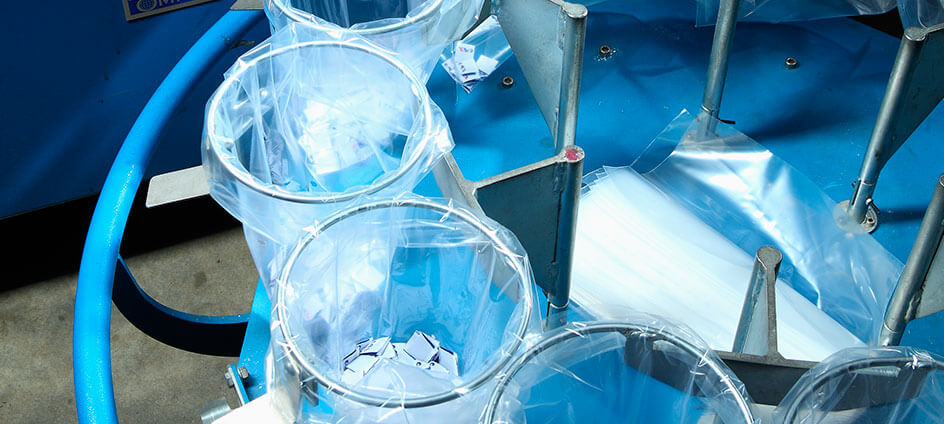

Packaging and finish

Regardless of your uses, we can propose bespoke, automated packaging suited to your requirements. We also have a reliable and bespoke logistics labelling service for full compliance with your specifications. We also control numerous finishes to offer you even more stand-out qualities: conventional cutting and laser cutting, folding, sealing, welding, perfuming, fitting of accessories, coating, etc.